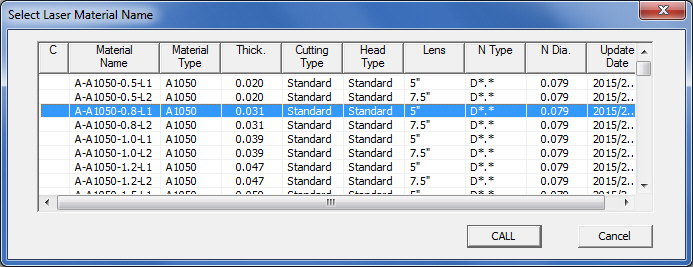

Different fiber optics material quality gases optical lenses cutting patterns etc will affect the cutting speed and need to be adjusted according to site conditions.

Amada fiber laser cutting conditions.

The laser source was developed by amada and it s the first high powered fiber laser designed for the sole purpose of cutting.

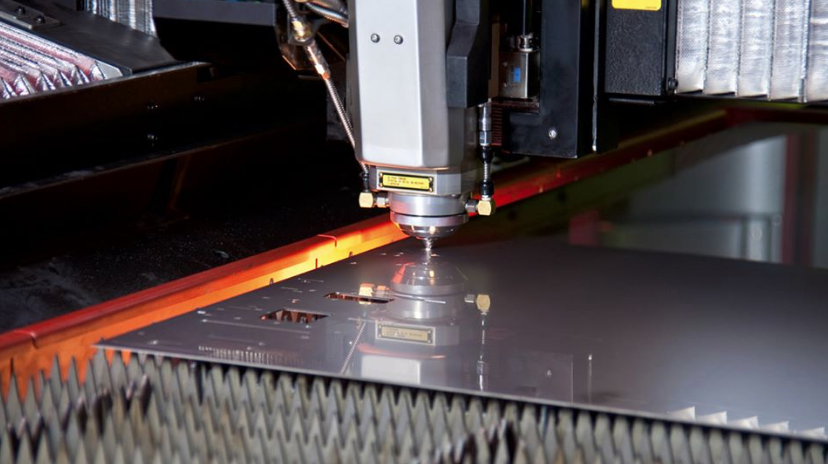

Fiber lasers generally have a bpp of 1 to 3 mm mrad which allows the laser to cut very fast in thinner materials yet the edge quality in the thicker materials.

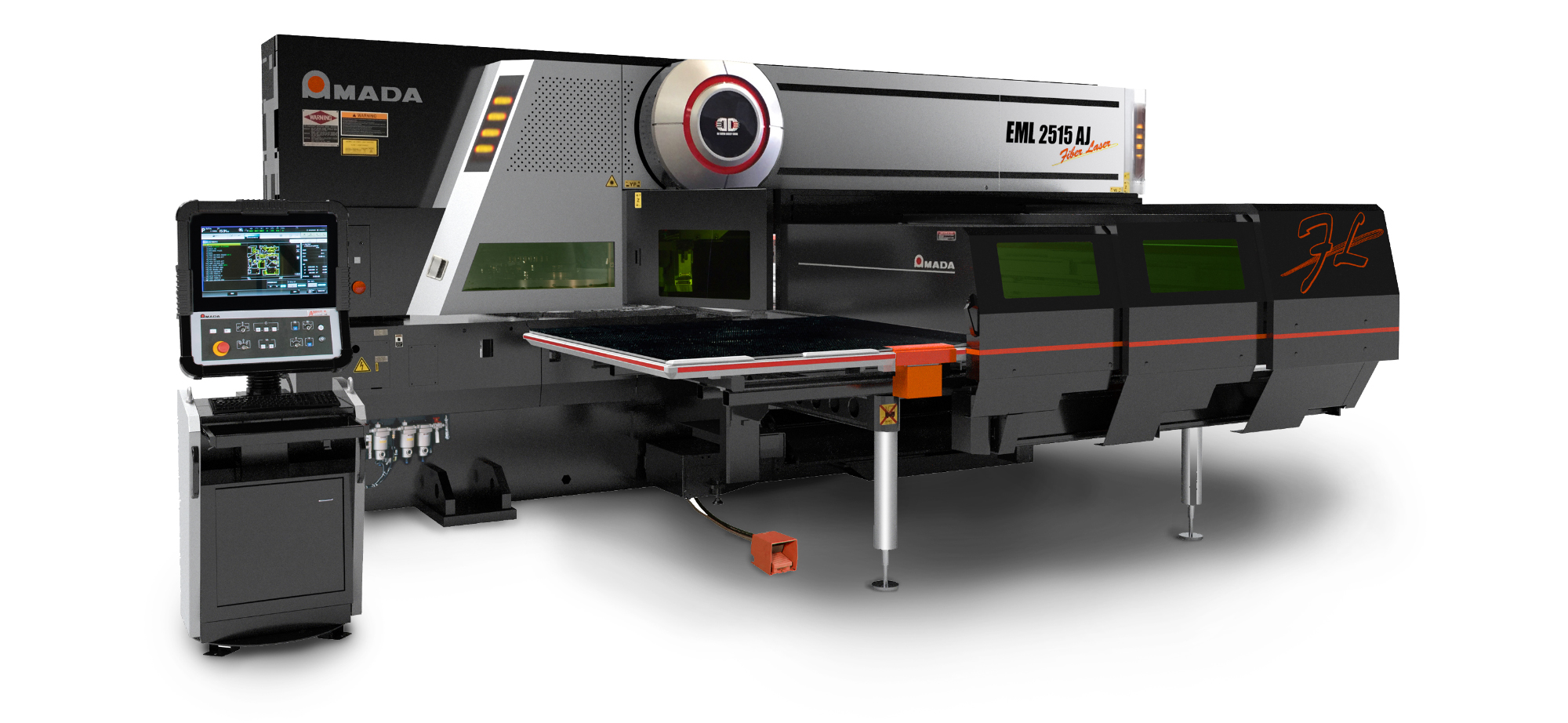

Amada a worldwide laser machine pioneer introduces the direct drive fiber laser cutting machine the lcg aj.

2 weeks ago i finally finished the installation and the amada technician here in israel came and did all the necessary procedures to turn the machine on.

Incorporating fiber laser cutting technology helps users process a variety of tubing and pipe with greater speeds compared to a co2 system.

The examples of the adjustments made will be similar for any co2 or fiber laser cutting mild steel with o2.

Given its dominance in the sheet metal cutting industry this article focuses on laser fusion cutting.

The following show 12 6 and 3 2 mm 1 2 1 4 and 10ga mild steel cut with oxygen on a 2kw fiber laser and examples of the same part cut with 1 variable changed to show how it affected the cut quality.

Using a laser beam with high energy density to heat the workpiece the temperature rises rapidly reaching the boiling point of the material in a very short period of time and the material begins to vaporize and form vapor.

Fiber lasers vs co 2.

Plain steel 1mm 10mm ss316 1mm 6mm.

The laser beam s quality is measured by the beam parameter product or bpp.

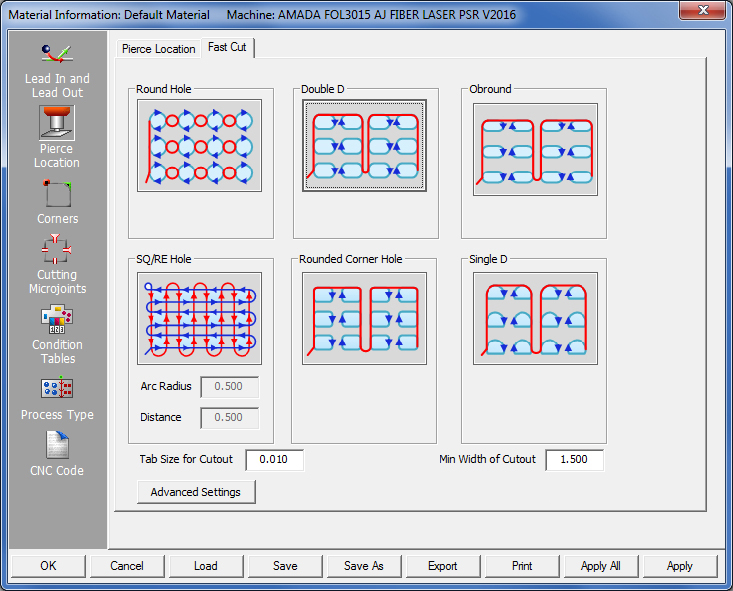

Adjustments occur automatically based on the cut condition selected on the machine s amnc 3i control.

Co 2 lasers generally have a bpp of 8 to 9 mm mrad which allows the laser to cut steel stainless and aluminum with very good edge quality.

Factors affect fiber laser cutting.

This fiber laser cutting machine delivers higher speed and faster acceleration processing by utilizing a carriage with a lower centre of gravity and the latest motion system incorporating high torque motors and helical rack drives.

Co 2 lasers use an electromagnetically stimulated gas typically a mixture.

The ensis was engineered specifically for manufacturers that require the high speed cutting capabilities of a fiber laser and the thick.

I have no prior experience with laser cutting machines but i m a fast learner.

The following data in the laser cutting thickness speed chart is for reference only.

Amada has engineered an advanced motion system.

This system has been specifically engineered to take full advantage of the unique cutting capabilities of fiber laser processing.

Developed by amada ensis technology infnitely changes the laser beam mode to effciently process thin to thick materials without additional machine setup.

If you d like to learn more about ablative laser cutting check out this article on micron scale manufacturing.

Factory cut chart settings.

For the last two weeks i ve been cutting material 8 hours a day.

Fiber laser cutting classification.